You’ll encounter various pressure gauge types, such as Bourdon tube, diaphragm, manometer, and digital transducers, each suited for specific applications. For analog gauges, check the scale units, note the needle position, and understand scale increments for accurate readings. Digital gauges display pressure directly but confirm the unit matches your system and that the gauge is zeroed. Regular calibration and maintenance guarantee reliability. Exploring further will enhance your ability to master precise pressure measurement techniques.

Common Types of Pressure Gauges and Their Applications

Pressure gauges come in several common types, each designed for specific measurement needs and environments.

You’ll often encounter Bourdon Tube gauges, which use a curved tube that straightens as pressure increases, offering reliable readings for industrial applications.

Diaphragm Gauges measure pressure through a flexible membrane, ideal for low-pressure or corrosive environments.

Manometer Types rely on liquid columns to indicate pressure differences, useful in laboratory settings.

Pressure Transducers convert pressure into electrical signals, allowing for digital monitoring and integration with control systems.

Understanding these types helps you select the right gauge for accuracy and durability in your specific context.

Step-by-Step Guide to Reading Analog and Digital Pressure Gauges

Although analog and digital gauges display measurements differently, both require careful interpretation to confirm accurate readings.

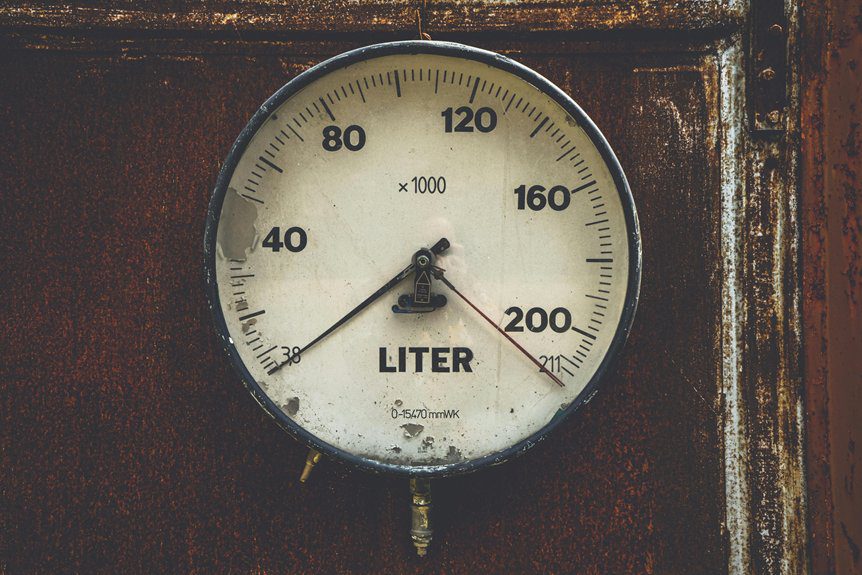

To read an analog gauge, first identify the measurement units and range. Observe the needle’s position relative to the scale, noting increments between markings.

For a digital gauge, simply read the numeric value shown on the display. Confirm the unit of measurement matches your system’s requirements.

Always verify the gauge is properly zeroed before taking a reading.

Tips for Accurate Pressure Measurement and Maintenance

When you want to guarantee accurate pressure measurements, regular maintenance and proper handling of your gauges are essential.

Implementing effective calibration techniques guarantees your readings remain reliable over time. Follow a consistent maintenance schedule to detect potential issues early.

Remember to:

- Inspect gauges regularly for physical damage or leaks

- Calibrate instruments according to manufacturer guidelines

- Keep gauges clean and free of debris

- Store gauges in stable environments to avoid temperature extremes

- Replace worn or faulty components promptly

Adhering to these practices helps maintain accuracy and extends your gauge’s lifespan in any application.

Frequently Asked Questions

How Do Temperature Variations Affect Pressure Gauge Accuracy?

Temperature variations impact pressure gauge accuracy by causing material expansion or contraction, which alters internal components and affects gauge performance.

When temperatures rise, the gauge’s metal parts can expand, leading to higher readings, while lower temperatures may cause contraction, resulting in lower readings.

These temperature effects can introduce measurement errors, so you should consider the operating environment and use temperature-compensated gauges or corrections to maintain precise readings.

Can Pressure Gauges Be Used for Corrosive Gas Measurement?

Yes, you can use pressure gauges for corrosive gas measurement, but you need to select gauges with materials resistant to corrosion, like stainless steel or specialized coatings.

Measurement techniques often involve isolating the gauge from direct contact using diaphragms or seals to prevent damage.

Choosing the right gauge type and protective features guarantees accurate readings while maintaining durability in corrosive environments.

Proper maintenance also plays a key role in reliable measurements.

What Certifications Are Important for Industrial Pressure Gauges?

You should look for certification standards such as ASME, ISO, and ANSI when selecting industrial pressure gauges.

These certifications confirm the gauges meet industry regulations for accuracy, safety, and reliability.

Additionally, certifications like ATEX or IECEx are essential if you work with explosive atmospheres.

Meeting these standards assures compliance with legal requirements and operational safety, helping you avoid costly penalties and maintain efficient monitoring in your industrial processes.

How to Calibrate a Pressure Gauge at Home?

To calibrate a pressure gauge at home, first secure a reliable reference gauge with known accuracy.

Connect both gauges to a pressure source, then gradually apply pressure and compare readings.

Note discrepancies and adjust your gauge using its calibration screw or dial if available.

Regular calibration techniques and gauge maintenance, such as cleaning and inspecting for damage, guarantee accurate measurements.

Always follow safety guidelines to prevent injury during this process.

What Are the Common Causes of Pressure Gauge Failure?

Common causes of pressure gauge failure include pressure leaks and mechanical wear.

If you notice pressure leaks, they often stem from loose connections or damaged seals, which reduce accuracy.

Mechanical wear occurs as moving parts inside the gauge degrade over time, leading to incorrect readings or total failure.

Exposure to extreme temperatures, vibration, or corrosive fluids can accelerate these issues.

Regular inspection and maintenance help you spot and prevent such problems early.